I picked up an old Power Designs TP340A bench power supply on eBay. The TP340A is a three channel (or “source) power supply. Source A & B have identical specs, providing up to 1A from 0-32v DC. They can be operated independently, or in tracking mode to provide positive and negative voltages. The third source only covers from 0-15v, but can deliver 5A at up to 6V and 2A at up to 15V. I bought it to power projects as I teach myself more about electronics. Little did I know what I was in for.

It showed up well-packed in great physical shape. There were a few scuff marks on the case where it had probably been pushed up against another piece of equipment, and some stickers and a few scuffs on the face plate, but otherwise, it looked nearly new.

When I took it apart, I found the insides were in similar condition.

On closer inspection though, I noticed something that wasn’t quite right

The 100 uF 25V Sprague electrolytic capacitor in postion C104 looked like it had a bad inner seal. I decided not to power up the PSU until I’d replaced this cap.

The other two channels have the same type of capacitor in the same position in the circuit. They looked Ok, but I decided they should be replaced too, and while I was at it, I figured I’d also order replacements for the other big electrolytic caps. This decision proved to be a mixed bag.

The visually intact sibling 100 uF Sprague caps proved dead when I tested them after replacing them. On the other hand, the other electrolytics were still in spec. Which is more than can be said about some of their replacements.

After replacing all the caps, I powered things up and was greeted by a wretched buzzing metallic groan . I quickly switched the power off and gathered my wits, such as they were. Then I turned it on again for long enough to twiddle some of the knobs, things still weren’t right, but I had slightly more information. I switched it off again, thought for a minute, and switched it on again. This time the horible groan was joined by a ffffffssstPOPffffff. I switched it off, but there was another ffffffssstPOPffffff. I’d put two of the capacitors in backwards and they’d vented.

I replaced the vented caps with the originals getting the polarity right this time, so I could see if I’d done the thing permanent harm. Happily, the horrid groaning sound didn’t return the next time I switched the power on. It didn’t work though.

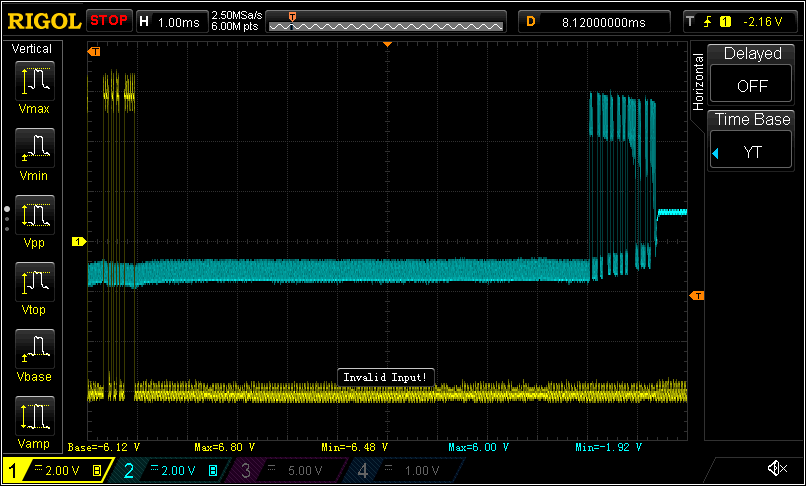

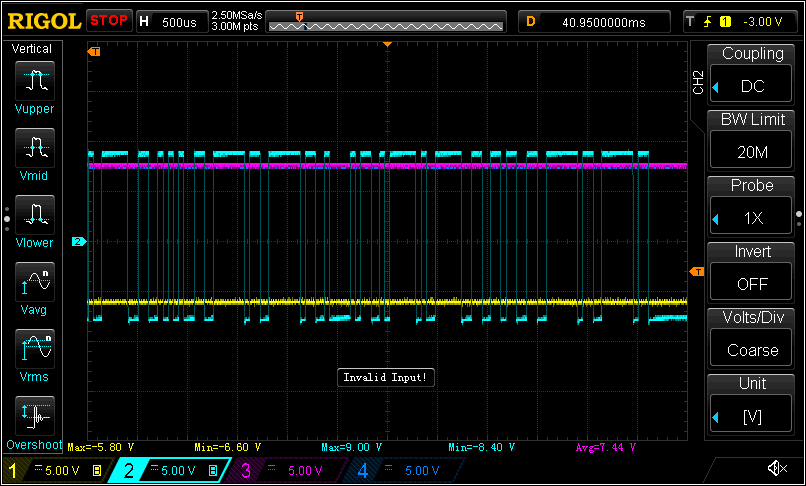

It didn’t take long to find them problem, I’d turned the voltage and current limit knobs the wrong way. After correcting that problem, I found that all the channels of the supply were fully functional, though things didn’t seem quite right. In tracking mode, source B didn’t respond at all until the voltage was up to about 8V and then started dropping off as it was turned up past 16v.

I started going through the troubleshooting steps in a PDF copy I’d found of the operating manual, but that’s going to be the subject of another post.

Today, I happened to stumble upon an

Today, I happened to stumble upon an